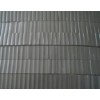

9A SOLID FILM LUBRICANT

HEAT CURING

SERIES E750

MEETS SAE SPEC AS5272C Type II

FORMERLY MIL-L-46010D TYPE II

TECHNICAL INFORMATION GUIDE

.

Lubricative Pigment Molybdenum Disulfide

Color Flat Dark Gray

Shelf Life 1 year from date of Manufacture

Vacuum Outgassing None @ 10-6 Torr.

Lox Compatibility 100% compatible and shock resistant

Resistivity 1.4 x 106 OHMS CM

Coefficient of Friction 0.0236 (Falex Test)

Load Carrying Capacity 2250 lbs. ASTM D2625 B

Corrosion Protection OVER 1500 hours* ASTM B117

(@ .0005" DFT on DoD-P-16232 Type M

Class 3 phosphated steel)

*Test halted before failure occurred

COMPOSITION AND PHYSICAL PROPERTIES

DEscriptION

Sandstrom 9A Dry Film Lubricant is a paint-like coating

containing molybdenum disulfide and corrosion inhibiting

pigments. This Heat Curing material prevents corrosion,

galling, seizing, and fretting. It is a low-friction coating which

exhibits long wear life when operated at -3200F to +5000F

under loads exceeding 100,000 psi.

9A should be applied where maximum wear life and corrosion

protection from a dry film lubricant are required.

once Sandstrom 9A has been heat cured, it is virtually

unaffected by atmospheric and fretting corrosion, solvents,

acids, oils, degreasers, and is not resoftened again at elevated

temperatures.

9A can be applied to a wide variety of surfaces by spraying

or dipping. Complete application instructions are on the

reverse of this sheet.

OUTSTANDING FEATURES/BENEFITS

Excellent Corrosion Protection, Chemical Resistance, and

Long Wear Life are its outstanding characteristics.

SANDSTROM 9A ConTAINS NO GRAPHITE

Use Sandstrom "099" as an alternative to 9A where low VOC

and no lead is preferred. 099's performance is comparable

to 9A.

TYPICAL USES

Sandstrom 9A is an excellent solution to the problem of lubricating

parts:

• That will be operated in corrosive atmospheres

• That may be stored for long periods

• Which are seldom lubricated once they leave the factory and

where permanent lubrication is desired

• Where operating pressures exceed the load-bearing capaci ties

of ordinary oils and greases

• Where "clean operation" is desired (9A will not collect dirt and

debris like grease and oils)

• Where a protective coating and sacrificial break-in lubricant

is needed

• Where fretting and galling is a problem (such as splines,

universal joints, and keyed bearings)

• Where easy release is desired (such as fasteners and PVC

molds)

• Where parts may be subjected to frequent disassembly

Net Wt./ Gallon 9.5 lbs. + .2 lb.

Solids Content 40% minimum (By Wt.)

Viscosity 40 - 46 sec (#1 Zahn cup @ 770F)

Flash Point 440F+ 20F Setaflash

Operating Temp. Range -3200F to +5000F

Vehicle Type Epoxy-Phenolic

VOC 5.5578 lbs./gal. minus water

(Theoretical)

Specifications: SAE Spec AS5272C

PRI QPL AS5272 type 2

Wear Life: 496 Minutes average

ASTM D2625 A

NOTICE

Before using this product, read all warnings and safety

information printed on the label, the Material Safety Data

Sheet, and the Technical Info-Guide

STIRRING

importANT! THIS LUBRICANT ConTAINS HEAVY PIGMENTS

WHICH SETTLE RAPIDLY. THEREFORE, IT SHOULD BE

STIRRED THOROUGHLY BEFORE USE AND CONTINUOUSLY

DURING APPLICATION.

THINNING

For spraying* - Use 2 parts 9A to 1 part PM solvent.

For dipping* - Use slow-drying thinner mixture of PM and PMA,

blended 1:1, as to provide proper run-off characteristics. The

suggested starting point is 4 parts 9A to 1 part thinner mixture.

*By volume.

APPLICATION

SANDSTROM 9A should be sprayed or dipped to the desired film

thickness (usually .0003 to .0007 inches). Allow parts to flash off at

least 30 minutes at 770F +50F.

BAKING

2439902778

2439902778